In the realm of woodworking, precision and efficiency are key to producing high-quality products. A double-headed woodworking tenoning machine is a versatile and advanced piece of equipment that offers numerous benefits to both hobbyists and professional woodworkers alike. Here's an exploration of the advantages this machine brings to the workshop.

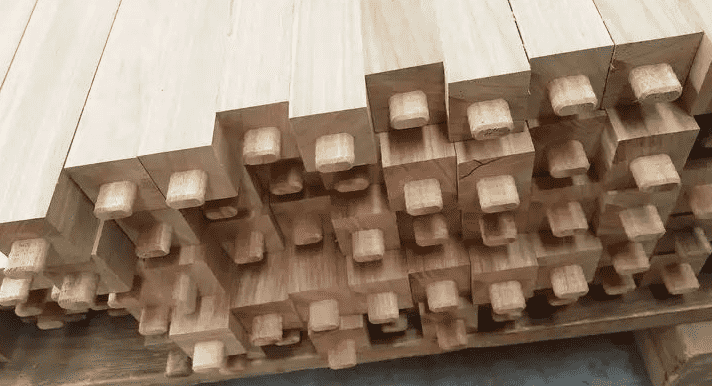

Woodworking is an art that requires not only creativity but also precision in execution. The tenoning process, which involves creating a tenon (a protruding part of wood that fits into a mortise), is crucial for creating strong and seamless joints. A double-headed woodworking tenoning machine is designed to streamline this process, offering a range of benefits that enhance productivity and result in superior craftsmanship.

Precision and Accuracy

One of the foremost benefits of a double-headed tenoning machine is its ability to deliver precision and accuracy. With two heads working in tandem, it ensures that tenons are cut to exact measurements, which is essential for creating tight and secure joints. This precision is particularly valuable when working on projects that require high standards of craftsmanship, such as furniture making or intricate architectural woodwork.

Increased Efficiency

The double-headed design allows for simultaneous or rapid consecutive operation on both sides of a piece of wood. This not only speeds up the tenoning process but also reduces the need for manual flipping or repositioning of the workpiece, thereby increasing overall efficiency and reducing production time.

Safety

Woodworking can be a hazardous activity, with the risk of injury from sharp tools and heavy machinery. A double-headed tenoning machine typically features built-in safety mechanisms, such as emergency stops and blade guards, which help to minimize the risk of accidents.

Time and Labor Savings

By automating the tenoning process, these machines save significant amounts of time and labor. This is particularly beneficial for larger projects or production runs, where the manual cutting of tenons could become time-consuming and labor-intensive.

Improved Product Quality

The use of a double-headed tenoning machine contributes to the overall quality of the finished product. Precise and accurate tenons lead to stronger joints, which are less likely to fail over time, resulting in a more durable and long-lasting product.In conclusion, a double-headed woodworking tenoning machine is a valuable addition to any woodworking shop. It offers a range of benefits, from increased precision and efficiency to versatility and safety. By investing in such a machine, woodworkers can elevate their craft, produce higher quality products, and streamline their workflow. As the woodworking industry continues to evolve, machines like the double-headed tenoner will play a pivotal role in shaping the future of this timeless craft.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?