Tel:

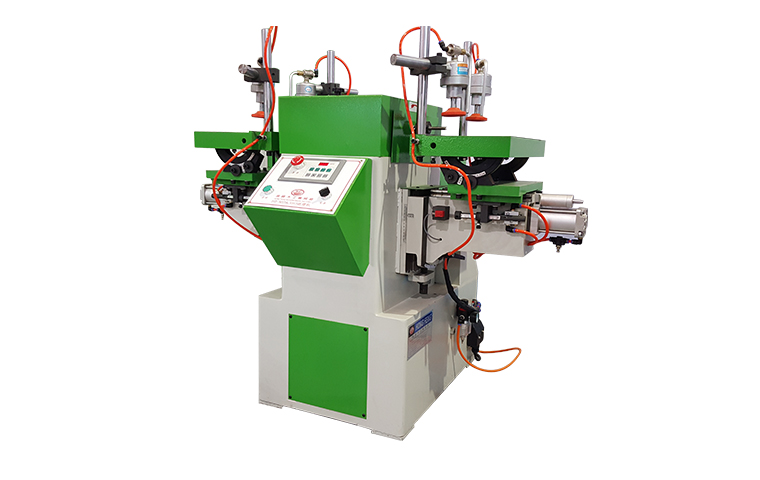

A double end milling machine is a powerful tool used in manufacturing and metalworking industries to perform intricate milling operations. This advanced machine operates on the principle of rotating multiple cutting tools simultaneously to achieve precise and efficient results.

The double end milling machine is equipped with two spindles, often arranged horizontally or vertically, each holding a cutting tool. This configuration enables the machine to perform simultaneous milling operations on both sides of the workpiece, significantly enhancing productivity and versatility.

Prior to the milling process, the workpiece needs to be firmly clamped onto a secure fixture or table. This ensures stability and accuracy during the operation. Various clamping mechanisms, such as vices or clamps, are employed depending on the geometry and size of the workpiece.

The cutting tools used in a double end milling machine vary depending on the material being machined and the desired outcome. Commonly used cutting tools include end mills, ball nose cutters, and face mills. These tools are carefully selected based on factors like material hardness, feed rate, and desired surface finish.

The milling process involves the rotation of the cutting tools against the workpiece to remove excess material and shape it according to specific dimensions. As the double end milling machine operates, each spindle rotates at precise speeds and feeds, ensuring accurate and uniform material removal. The machine operator may adjust the cutting parameters based on the material and desired outcome.

Operating a double end milling machine requires strict adherence to safety protocols. Safety measures, such as proper training, wearing protective equipment, and securing the work area, must be followed to prevent accidents and injuries. Additionally, regular maintenance checks and inspections help identify any potential hazards and keep the machine in optimal working condition.

A double end milling machine is a highly efficient and versatile tool for performing precision milling operations. Its dual spindle configuration, workpiece clamping mechanism, cutting tools selection, milling process, and adherence to safety measures all contribute to its functionality and reliability. Understanding how this sophisticated machine works paves the way for successful and accurate machining operations in various industries.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?