Tel:

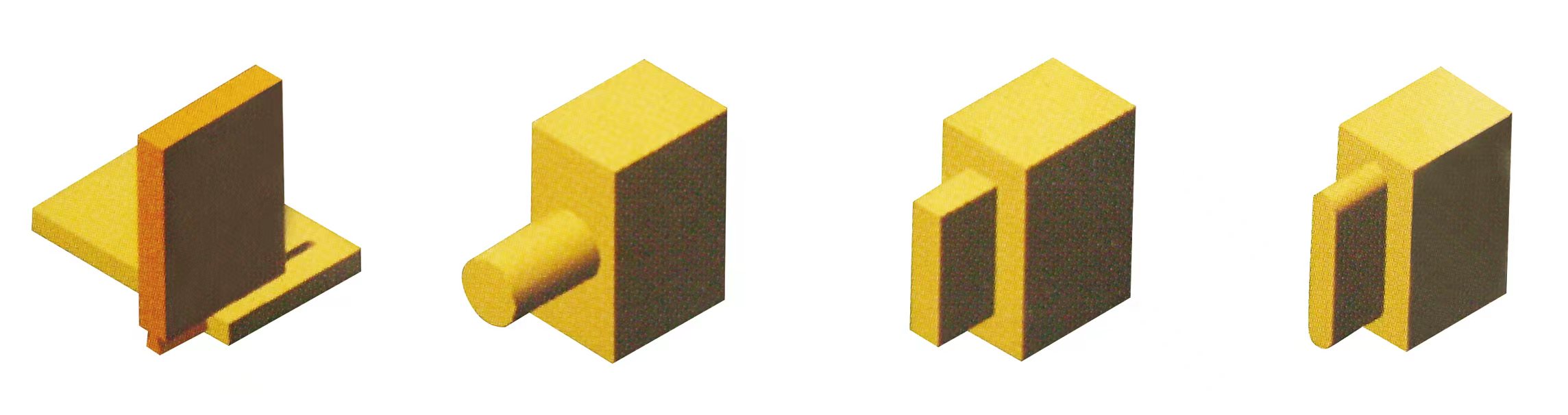

As the manufacturing industry continues to embrace automation and precision, the utilization of CNC dovetail machines has become increasingly prevalent. These machines offer a range of applications across various industries, providing efficient and accurate solutions for intricate joinery. Let's delve into the diverse domains where CNC dovetail machines are used.

In the woodworking industry, CNC dovetail machines have revolutionized the production of furniture, cabinetry, and wooden crafts. These machines excel in creating strong and aesthetically pleasing dovetail joints that ensure the durability of wooden structures. With their ability to precisely cut dovetail patterns, CNC dovetail machines simplify the manufacturing process and enhance the overall quality of woodwork.

CNC dovetail machines find extensive application in the automotive manufacturing sector. These machines are crucial in seamlessly assembling components, such as engine blocks, transmission cases, and axle shafts. By accurately cutting dovetail joints, CNC dovetail machines ensure the proper fit and alignment of various automotive parts, enhancing the overall performance and reliability of vehicles.

The electronics industry heavily relies on CNC dovetail machines to facilitate efficient and precise production. These machines are used to create dovetail slots and grooves in electronic device casings, ensuring secure and seamless integration of components. CNC dovetail machines enable manufacturers to meet the rigorous demands for precision and reliability in the production of smartphones, laptops, and other electronic devices.

With their ability to produce intricate dovetail joints, CNC dovetail machines play a vital role in the manufacturing of medical equipment. These machines are utilized in the production of surgical instruments, implants, and prosthetics, ensuring precise and durable connections. CNC dovetail machines contribute to the advancements in medical technology by providing reliable and accurate joinery solutions.

In the aerospace industry, CNC dovetail machines are extensively employed in the fabrication of aircraft components. These machines are utilized to create precise dovetail connections in structural parts, such as wing spars, engine mounts, and landing gear. By guaranteeing the accuracy and strength of dovetail joints, CNC dovetail machines contribute to the safety and efficiency of aerospace systems.

In conclusion, CNC dovetail machines find wide-ranging applications in industries such as woodworking, automotive manufacturing, electronics, medical equipment manufacturing, and aerospace. With their precise cutting capabilities, these machines enable the production of strong and intricate dovetail joints that enhance the overall quality, performance, and reliability of various products. The utilization of CNC dovetail machines not only streamlines manufacturing processes but also ensures the durability and longevity of assembled components. Embracing the potential of CNC dovetail machines can lead to significant advancements in various sectors, driving innovation and progress in the manufacturing industry.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?