Tel:

CNC (Computer Numerical Control) double-end tenon machines have revolutionized the woodworking industry with their precision, efficiency, and versatility. These advanced machines offer numerous benefits that enhance productivity, quality, and profitability for woodworking businesses. In this article, we'll delve into the advantages of using CNC double-end tenon machines and how they contribute to the success of woodworking operations.

1. Enhanced Precision and Accuracy:

One of the primary benefits of CNC double-end tenon machines is their ability to deliver unparalleled precision and accuracy in woodworking tasks. With computer-controlled cutting and shaping processes, these machines can produce tenons with tight tolerances and consistent dimensions, ensuring uniformity across multiple pieces. This precision eliminates errors and discrepancies commonly associated with manual woodworking methods, resulting in higher-quality finished products.

2. Increased Efficiency and Productivity:

CNC double-end tenon machines automate repetitive tasks and streamline production processes, leading to significant gains in efficiency and productivity. These machines can perform multiple operations, such as cutting, shaping, and profiling, in a single setup, reducing downtime and maximizing throughput. By eliminating the need for manual intervention and optimizing workflow, CNC machines enable woodworking businesses to meet tight deadlines, fulfill large orders, and increase overall output.

3. Versatility in Woodworking Applications:

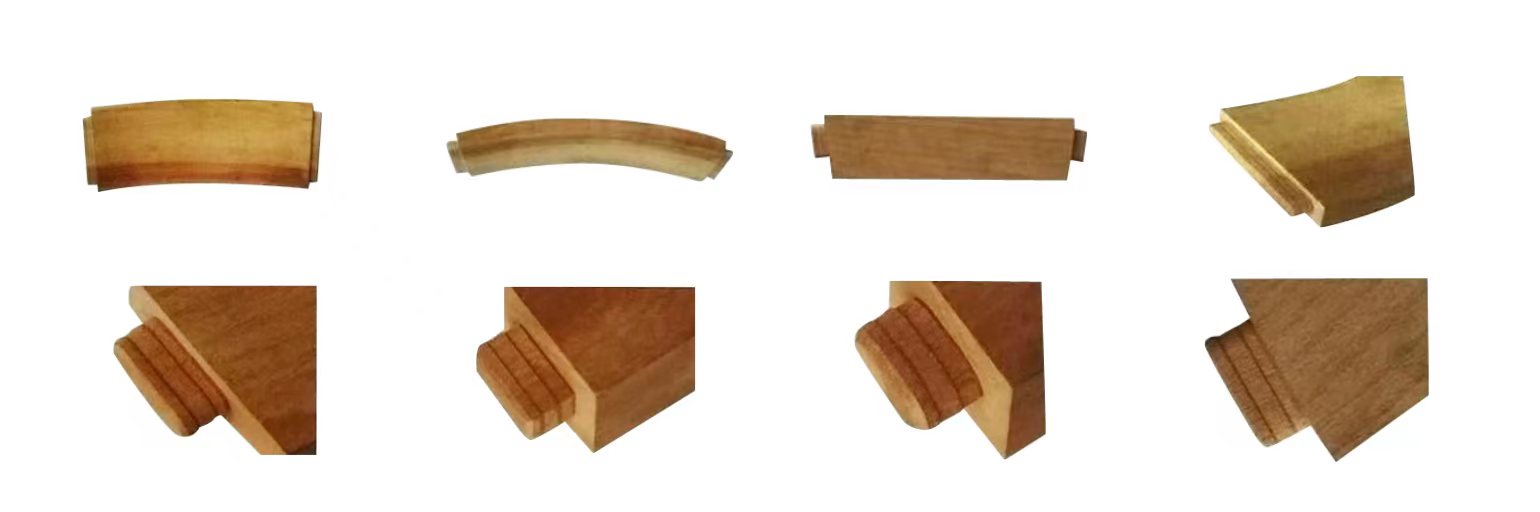

CNC double-end tenon machines offer versatility in handling a wide range of woodworking applications and materials. Whether it's crafting furniture, cabinetry, doors, or windows, these machines can accommodate various wood types, sizes, and shapes with ease. With customizable tooling options and programming capabilities, CNC machines empower woodworkers to create intricate designs and achieve desired aesthetics, expanding the scope of their woodworking projects.

4. Reduction in Material Waste:

Efficient material utilization is crucial in woodworking to minimize waste and maximize yield. CNC double-end tenon machines optimize cutting paths and nesting layouts to minimize scrap and optimize material usage. By precisely cutting tenons with minimal kerf and optimizing part placement, these machines reduce material waste and lower production costs. This sustainable approach not only benefits the bottom line but also reduces environmental impact.

5. Improved Safety and Ergonomics:

CNC double-end tenon machines incorporate advanced safety features and ergonomic design elements to ensure a safe and comfortable working environment for operators. With automated cutting and tool-changing processes, these machines minimize the risk of accidents and injuries associated with manual woodworking equipment. Additionally, ergonomic controls and intuitive interfaces enhance operator comfort and efficiency, reducing fatigue and improving overall productivity.

6. Streamlined Design and Production Workflow:

Integration with CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software enables seamless communication between design and production processes. Woodworkers can create, edit, and visualize designs digitally before executing them on CNC double-end tenon machines. This streamlined workflow eliminates errors, reduces setup time, and accelerates production cycles, allowing woodworking businesses to respond quickly to customer demands and market trends.

7. Scalability and Adaptability:

CNC double-end tenon machines offer scalability and adaptability to accommodate changing production needs and business growth. Whether it's scaling up production volume, diversifying product offerings, or integrating new technologies, these machines can adapt to evolving requirements with minimal disruption. With modular construction and upgradable components, CNC machines provide a future-proof investment that can grow and evolve alongside woodworking businesses.

Conclusion:

In conclusion, CNC double-end tenon machines offer a myriad of benefits that elevate woodworking operations to new heights of efficiency, precision, and productivity. From enhanced precision and increased efficiency to versatility in applications and reduced material waste, these machines empower woodworking businesses to achieve greater success and competitiveness in today's dynamic market. By leveraging the advantages of CNC technology, woodworking professionals can unlock new possibilities and drive innovation in the industry.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?