Tel:

CNC tenon and mortise machines are advanced woodworking tools that offer precision, efficiency, and versatility in creating strong and precise joints. In this article, we will delve into the working principles of CNC tenon and mortise machines, highlighting their functionalities and the benefits they offer to woodworking professionals. Additionally, we'll explore the role of CNC mortiser suppliers and tenoning machine factories in providing these cutting-edge machines to the woodworking industry.

Introduction to CNC Tenon and Mortise Machines:

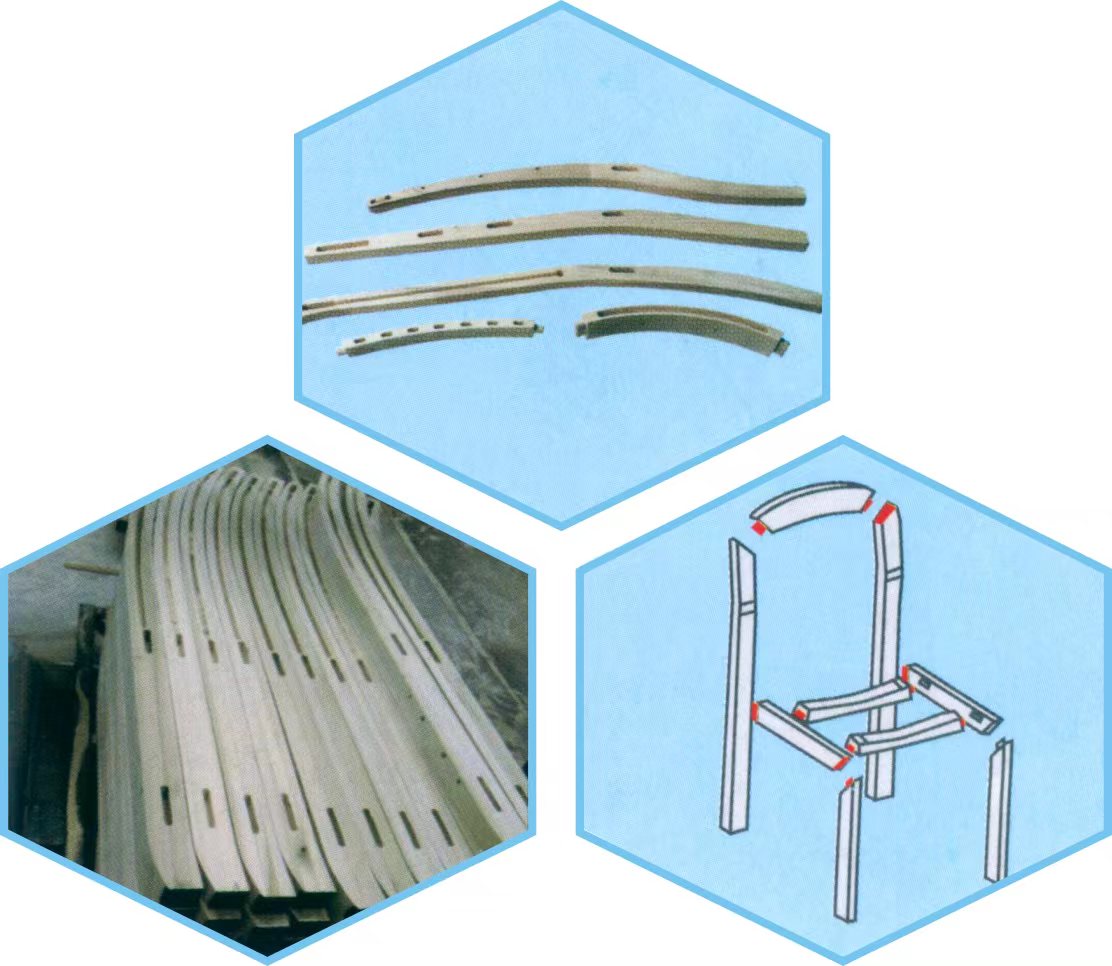

CNC tenon and mortise machines are automated woodworking machines designed to produce tenon and mortise joints with exceptional accuracy and consistency. These joints are commonly used in furniture making, cabinetry, joinery, and other woodworking applications to create strong and durable connections between wooden components.

Working Principles of CNC Tenon and Mortise Machines:

1.Design Input: The operation of CNC tenon and mortise machines begins with the input of design specifications into the machine's computer system. Woodworking professionals use specialized software to create precise designs of the tenon and mortise joints, specifying dimensions, angles, and other parameters.

2.Material Preparation: Once the design is finalized, woodworking professionals prepare the workpieces by selecting suitable wood stock and cutting them to the required dimensions. The workpieces are then securely clamped onto the machine's worktable to ensure stability during the machining process.

3.Tool Selection and Setup: CNC tenon and mortise machines are equipped with a variety of cutting tools, including drills, end mills, and saw blades, tailored for specific woodworking tasks. Woodworking professionals select the appropriate tools and set them up on the machine's spindle, ensuring proper alignment and tool clearance.

4.Machining Process: With the workpieces securely positioned and the cutting tools in place, the machining process begins. The CNC controller precisely guides the movement of the cutting tools along the programmed toolpaths, accurately shaping the tenon and mortise joints according to the design specifications.

5.Precision and Accuracy: CNC tenon and mortise machines offer unparalleled precision and accuracy in creating tenon and mortise joints, ensuring tight fits and seamless connections between wooden components. Advanced servo motors, ball screws, and linear guides enable smooth and precise movement of the cutting tools, resulting in high-quality joints.

6.Automation and Efficiency: By automating the machining process, CNC tenon and mortise machines significantly improve productivity and efficiency in woodworking operations. Woodworking professionals can produce a large volume of tenon and mortise joints with minimal manual intervention, reducing labor costs and lead times.

Role of CNC Mortiser Suppliers and Tenoning Machine Factories:

CNC mortiser suppliers and tenoning machine factories play a crucial role in providing woodworking professionals with access to advanced CNC tenon and mortise machines. These suppliers design, manufacture, and distribute CNC machines tailored to the specific needs and requirements of woodworking industries.

1.Product Development: CNC mortiser suppliers and tenoning machine factories invest in research and development to continuously improve the design, functionality, and performance of their CNC machines. They incorporate the latest technological advancements and innovations to meet the evolving needs of woodworking professionals.

2.Quality Assurance: CNC mortiser suppliers and tenoning machine factories adhere to stringent quality control standards throughout the manufacturing process to ensure the reliability, durability, and precision of their CNC machines. Each machine undergoes rigorous testing and inspection to verify its performance and accuracy.

3.Technical Support and Training: In addition to supplying CNC machines, CNC mortiser suppliers and tenoning machine factories offer comprehensive technical support, training, and after-sales services to woodworking professionals. They provide assistance with machine installation, operation, maintenance, and troubleshooting, ensuring optimal performance and uptime.

4.Customization Options: CNC mortiser suppliers and tenoning machine factories understand that woodworking professionals have unique requirements and preferences. Therefore, they offer customization options to tailor CNC machines to specific woodworking applications, such as varying workpiece sizes, materials, and joint configurations.

Conclusion:

In conclusion, CNC tenon and mortise machines represent the pinnacle of precision and efficiency in woodworking operations. By leveraging advanced CNC technology, these machines enable woodworking professionals to create strong and precise tenon and mortise joints with ease. CNC mortiser suppliers and tenoning machine factories play a vital role in providing woodworking professionals with access to cutting-edge CNC machines, offering quality products, technical support, and customization options. With CNC tenon and mortise machines, woodworking professionals can elevate their craftsmanship, improve productivity, and achieve superior results in their woodworking projects.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?