Tel:

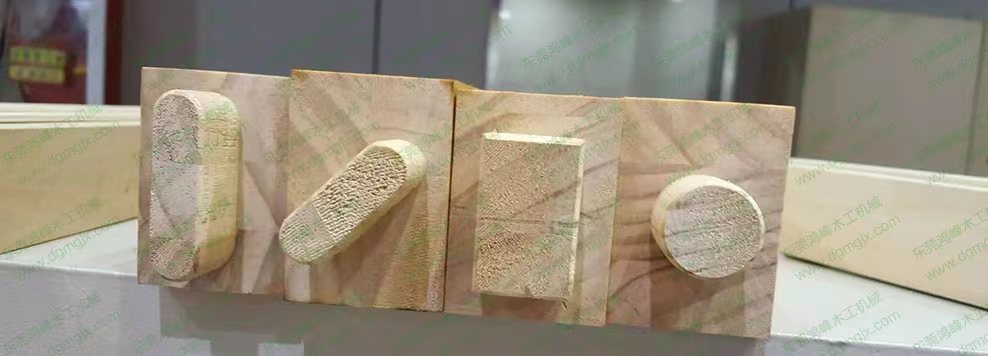

CNC tenon machines are advanced and highly efficient tools used for woodworking operations. To ensure their longevity, efficiency, and optimal performance, proper maintenance is essential. This article provides a comprehensive guide on the necessary maintenance tasks for CNC tenon machines.

Cleanliness is crucial for the smooth functioning of CNC tenon machines. Regularly cleaning the machine components, such as the work table, clamps, and cutting tools, prevents the buildup of debris and dust. It is recommended to use non-abrasive cleaning agents and soft brushes to avoid damaging the surfaces.

In addition, lubrication plays a vital role in maintaining the machine's performance. It is important to regularly lubricate the moving parts, such as the guide rails and ball screws, using the appropriate lubricants specified by the machine manufacturer.

To ensure precise and accurate cuts, proper calibration and alignment of the CNC tenon machine are essential. Regularly checking and adjusting the machine's settings, such as the tool height, cutting depth, and spindle alignment, is necessary to maintain optimal performance. Utilizing specialized calibration tools and following the manufacturer's guidelines is recommended for accurate calibration.

With regular use, certain parts of the CNC tenon machine can become worn or damaged. Regular inspection of critical components, such as the cutting tools, belts, and motors, helps identify any signs of wear and tear. Worn parts should be promptly replaced to prevent further damage and ensure the machine's consistent performance. Keeping a spare parts inventory and following the manufacturer's recommended replacement schedule is advisable.

CNC tenon machines are often equipped with advanced software systems that control their operations. Regularly updating and maintaining the machine's software ensures compatibility with new technologies and bug fixes. It is crucial to follow the manufacturer's instructions for software updates and perform regular backups to prevent data loss.

Proper operator training is a vital aspect of CNC tenon machine maintenance. Well-trained operators can identify potential issues, perform basic troubleshooting, and handle the machine safely. Regular safety training should be provided to ensure operators use appropriate personal protective equipment and adhere to safety guidelines when operating the machine.

In conclusion, maintaining CNC tenon machines is essential for their longevity, accuracy, and optimal performance. Regular cleaning, lubrication, calibration, and inspection of critical parts are crucial. Additionally, keeping the software updated and ensuring operators are well-trained will contribute to the safe and efficient operation of CNC tenon machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?