Tel:

CNC (Computer Numerical Control) miter machines represent a significant advancement in precision cutting technology, offering manufacturers unparalleled accuracy and efficiency in various industries. These machines are utilized for cutting materials such as wood, metal, and plastic with precise angles, making them invaluable assets in manufacturing processes where precision is paramount. In this article, we'll delve into the intricacies of how CNC miter machines work, exploring their components, operation, and the role of CNC miter machine manufacturers, factories, and suppliers in delivering these cutting-edge solutions.

CNC miter machines consist of several essential components that work together to execute precise cuts according to programmed specifications:

Control System: The control system of a CNC miter machine consists of computer software that interprets programming instructions and translates them into precise movements of the cutting tool.

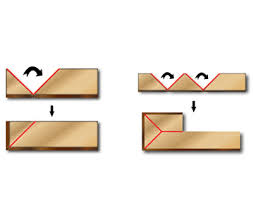

Cutting Head: The cutting head is the part of the machine that holds the cutting tool, such as a saw blade or milling cutter. It can move along multiple axes to perform angled cuts.

Workpiece Holding Mechanism: A CNC miter machine requires a mechanism to securely hold the workpiece in place during the cutting process. This can include clamps, vices, or specialized fixtures tailored to the specific material being cut.

Drive Mechanism: The drive mechanism of a CNC miter machine provides the power necessary to move the cutting head and position it accurately relative to the workpiece. This can involve servo motors, ball screws, and linear guides.

Coolant System: Some CNC miter machines are equipped with a coolant system to prevent overheating of the cutting tool and workpiece during the cutting process, especially when working with metals.

The operation of a CNC miter machine involves several steps:

Design and Programming: The cutting process begins with the design of the desired part or component using CAD (Computer-Aided Design) software. Once the design is complete, CAM (Computer-Aided Manufacturing) software is used to generate toolpaths and convert the design into a series of instructions for the CNC miter machine.

Loading the Workpiece: The workpiece is securely clamped or fixtured in place on the machine's worktable, ensuring stability and accuracy during the cutting process.

Tool Setup: The appropriate cutting tool, such as a saw blade or milling cutter, is selected and installed in the cutting head of the machine.

Execution of Program: The CNC miter machine operator initiates the cutting process by loading the programmed instructions into the machine's control system. The machine then executes these instructions, moving the cutting head along the programmed toolpaths to precisely cut the workpiece according to the design specifications.

Quality Control: Throughout the cutting process, operators may perform periodic checks to verify the accuracy and quality of the cuts being produced. Adjustments can be made as necessary to ensure that the finished parts meet the required specifications.

Unloading the Finished Parts: Once the cutting process is complete, the finished parts are removed from the machine's worktable and inspected for quality. They may then undergo further processing or assembly as needed.

CNC miter machine manufacturers, factories, and suppliers play a crucial role in the development, production, and distribution of these sophisticated machining systems:

Research and Development: CNC miter machine manufacturers invest in research and development to continuously improve the design, functionality, and performance of their machines. This involves incorporating the latest advancements in technology, materials, and manufacturing processes to enhance precision, reliability, and efficiency.

Production and Assembly: CNC miter machine factories are responsible for the production and assembly of these complex machines. Skilled technicians and engineers work together to manufacture the various components, assemble them into complete machines, and perform rigorous testing to ensure quality and performance standards are met.

Distribution and Sales: CNC miter machine suppliers are responsible for distributing these machines to customers worldwide. They work closely with manufacturers and end-users to understand their specific requirements and provide customized solutions tailored to their needs. Additionally, suppliers offer technical support, training, and after-sales service to ensure optimal performance and customer satisfaction.

In conclusion, CNC miter machines represent a pinnacle of precision cutting technology, offering manufacturers the ability to produce complex parts and components with exceptional accuracy and efficiency. Understanding how these machines work, from their intricate components to their operation, provides valuable insight into their capabilities and potential applications across various industries. Furthermore, the role of CNC miter machine manufacturers, factories, and suppliers is indispensable in delivering cutting-edge solutions that meet the evolving needs of modern manufacturing. As technology continues to advance, CNC miter machines will undoubtedly remain at the forefront of innovation, driving productivity, quality, and competitiveness in the global market.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?