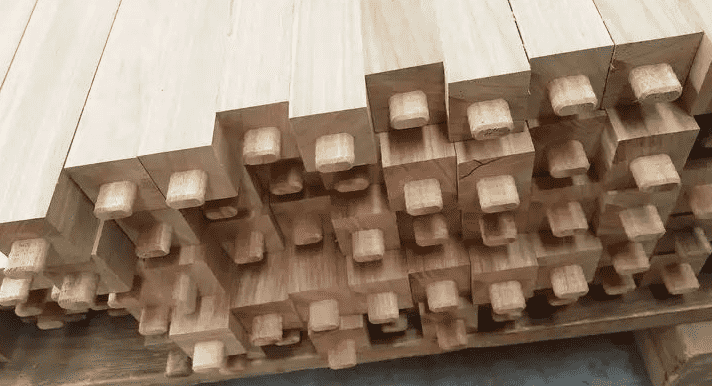

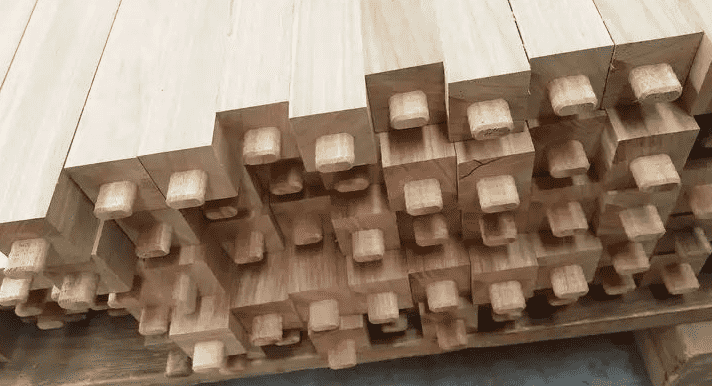

The mortise and tenon joint is a fundamental element in woodworking, providing a strong and durable connection between two pieces of wood. To create these joints efficiently and accurately, woodworkers often turn to specialized machinery known as mortising machines. Here's a detailed look at how a mortise machine operates and its role in the woodworking process.

A mortising machine is a type of woodworking equipment designed to cut mortises, which are square or rectangular holes, into wood. These machines are crucial for creating the mortise part of the mortise and tenon joint, a traditional method of joining pieces of wood together without the need for nails or screws.

Components of a Mortising Machine

- Cutting Head: The heart of the machine, the cutting head contains the bits or chisels that actually cut the mortise.

- Feed System: This component moves the wood into the cutting head, ensuring precise positioning for the mortise.

- Control Panel: Modern mortising machines often feature a control panel that allows for adjustments in depth, width, and position of the mortise.

- Worktable: Provides a stable surface to hold the wood in place during the cutting process.

Types of Mortising Machines

- Manual Mortising Machines: Operated by hand, these machines require the woodworker to manually control the feed and depth of the cut.

- Semi-Automatic Mortising Machines: Incorporate some level of automation, such as automatic feed systems, but may still require manual positioning.

- CNC Mortising Machines: Utilize computer numerical control to automate the entire process, allowing for complex and precise mortise patterns to be cut with minimal human intervention.

Working Principle of a Mortising Machine

- Setup: The woodworker sets up the machine by adjusting the depth and width of the cutting head to match the specifications of the mortise needed.

- Positioning: The wood is securely clamped onto the worktable, ensuring it is properly aligned with the cutting head.

- Cutting Process: The machine's feed system moves the wood into the cutting head, which contains rotating bits that remove material to create the mortise.

- Repetition: For multiple mortises, the machine can be set to repeat the process at specified intervals, creating a series of mortises in a single operation.

Applications of Mortising Machines

Mortising machines are used in a variety of woodworking applications, including:

- Furniture making, for joints in chairs, tables, and cabinets.

- Construction, for creating structural joints in wooden frames.

- Restoration work, to replicate historical mortise and tenon joints in antique furniture.

Benefits of Using a Mortising Machine

- Precision: Ensures that each mortise is cut to exact specifications, leading to a stronger and more stable joint.

- Efficiency: Reduces the time and labor required to create multiple mortises, especially when compared to hand tools.

- Consistency: Provides uniform mortises, which is essential for professional-quality woodworking projects.

The mortise machine is an indispensable tool in modern woodworking, offering a combination of precision, efficiency, and versatility. Whether you're a professional furniture maker, a construction worker, or a DIY enthusiast, a well-chosen mortising machine can significantly enhance your woodworking capabilities. With the right machine, you can create strong, durable, and visually appealing mortise and tenon joints with ease.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?