Tel:

In the ever-evolving woodworking industry, CNC (Computer Numerical Control) machinery has emerged as a game-changer. These advanced machines offer unparalleled precision, efficiency, and versatility, making them indispensable tools for modern woodworkers. In this article, we'll explore the numerous advantages of CNC woodworking machinery, highlighting why investing in a woodworking CNC machine, CNC machine for wood, or CNC woodworking machine is a smart choice for any woodworking professional or hobbyist.

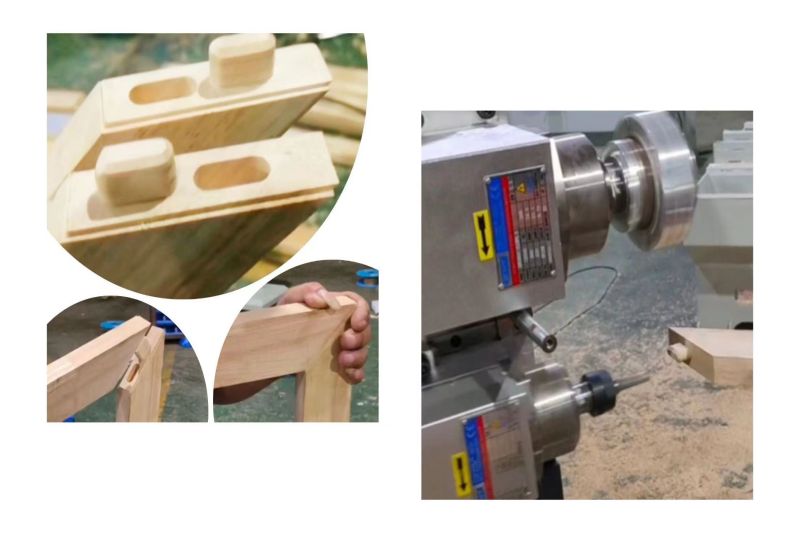

One of the most significant advantages of CNC woodworking machines is their ability to deliver unmatched precision and accuracy. Traditional woodworking methods rely heavily on manual measurements and cuts, which can lead to inconsistencies and errors. In contrast, a CNC machine for wood operates with computer-guided precision, ensuring that every cut, carve, and contour is executed with exacting detail. This precision is particularly beneficial for complex designs and intricate patterns, where even the slightest deviation can ruin the final product.

CNC woodworking machines are designed to maximize efficiency and productivity. Unlike manual woodworking, which can be time-consuming and labor-intensive, CNC machines automate the cutting, shaping, and carving processes. Once the design is programmed into the machine, it can produce multiple identical pieces with minimal human intervention. This automation not only speeds up production but also allows woodworkers to focus on other critical tasks, thereby increasing overall productivity.

A woodworking CNC machine offers remarkable versatility, capable of handling a wide range of tasks and materials. Whether working with hardwood, softwood, plywood, or MDF, a CNC woodworking machine can cut, carve, engrave, and drill with ease. Moreover, these machines can execute a variety of design styles, from simple cuts to intricate 3D carvings. This versatility makes CNC machines ideal for custom furniture, cabinetry, decorative pieces, and more.

Consistency is a key advantage of CNC woodworking machinery. When producing multiple units of the same design, maintaining uniformity is crucial. CNC machines excel in this regard, as they can replicate the same design countless times with consistent accuracy. This repeatability ensures that each piece meets the same high standards, reducing waste and minimizing the need for rework.

Efficient material use is another benefit of CNC woodworking machines. Traditional woodworking methods often result in significant material waste due to human error and imprecise cuts. CNC machines, however, optimize the cutting process to minimize waste. By using computer-aided design (CAD) software, woodworkers can plan and visualize cuts before executing them, ensuring maximum material utilization and reducing costs.

Safety is a paramount concern in any woodworking shop. CNC woodworking machines enhance safety by reducing the need for direct human interaction with cutting tools. The automated nature of these machines means that operators are less exposed to potential hazards, such as kickbacks, flying debris, and accidental cuts. Additionally, modern CNC machines are equipped with safety features like emergency stop buttons and protective enclosures, further ensuring a safe working environment.

For woodworking businesses, scalability is essential for growth and profitability. Investing in a CNC machine for wood allows businesses to scale their operations efficiently. The ability to produce high-quality, consistent products quickly and with minimal labor enables businesses to take on larger orders and meet tight deadlines. This scalability can lead to increased revenue and a competitive edge in the market.

While the initial investment in a CNC woodworking machine may be significant, the long-term benefits outweigh the costs. The increased efficiency, reduced material waste, and enhanced productivity translate into significant cost savings over time. Additionally, the ability to take on more complex and high-value projects can lead to higher profit margins, making CNC machines a cost-effective solution for serious woodworkers.

CNC woodworking machinery represents a revolutionary advancement in the woodworking industry. The advantages of using a woodworking CNC machine, CNC machine for wood, or CNC woodworking machine are clear: unmatched precision, increased efficiency, versatility, consistency, reduced material waste, enhanced safety, scalability, and long-term cost-effectiveness. For woodworkers looking to elevate their craft and stay competitive, investing in CNC technology is a wise and strategic decision. Embrace the future of woodworking with CNC machinery and experience the transformative impact it can have on your work.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?