Tel:

In the world of woodworking, precision and efficiency are paramount. As demands for intricate designs and faster production increase, the need for advanced machinery becomes evident. The CNC Mortising Machine is a prime example of how technology is revolutionizing the woodworking industry.

1. The Role of CNC Mortising Machines

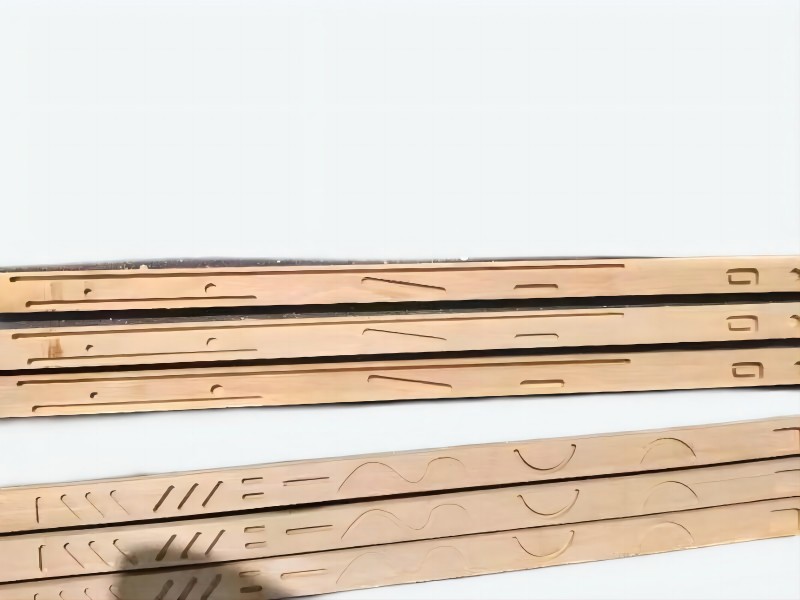

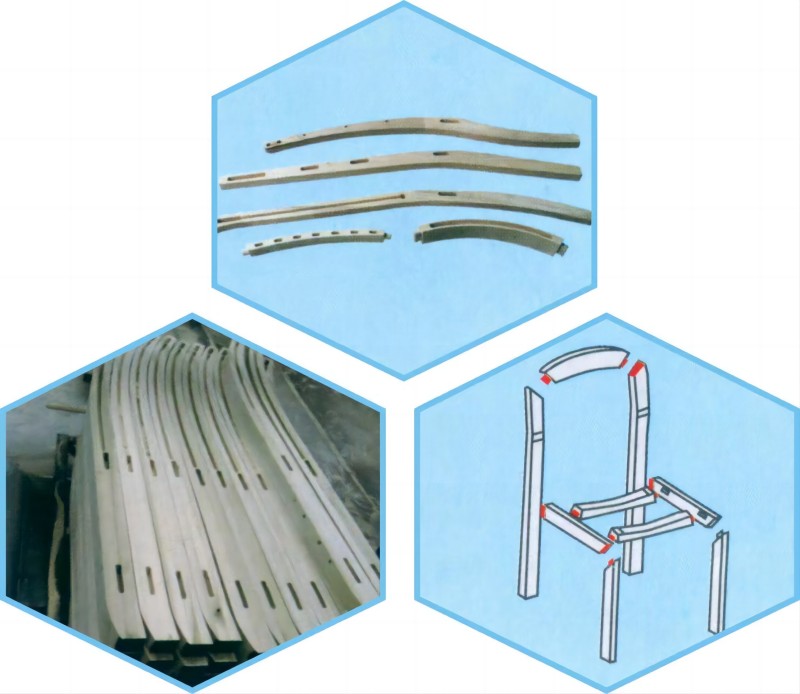

CNC Mortising Machines have become a staple in modern woodworking shops, particularly for tasks that require precise and consistent groove cutting. These machines are designed to handle a variety of tasks, including milling straight and profiled grooves, as well as creating hole grooves. With the ability to perform complex cuts with minimal manual intervention, CNC Mortising Machines save time while ensuring high-quality results.

2. Key Features and Specifications

The CNC Mortising Machines are equipped with several key features that make them indispensable in woodworking:

Wizard-Style Data Input: One of the standout features of these machines is their wizard-style data input system. This user-friendly interface allows operators to input data quickly and accurately, reducing the chances of errors and streamlining the setup process. The intuitive design of the interface makes it accessible even to those with limited experience in CNC operations.

Powerful Servo Motors: The X, Y, and Z-axis are driven by powerful servo motors, ensuring smooth and precise movements. This is particularly important when working with complex designs that require high levels of accuracy. The servo motors provide the necessary torque and control, allowing the machine to handle a wide range of materials with ease.

High-Speed Spindle: The machine's spindle operates at a high speed, enabling it to cut through materials quickly and efficiently. The spindle's power, combined with the machine's sturdy construction, ensures that even the toughest materials can be processed with minimal wear and tear on the machine.

Versatile Cutting Capabilities: Whether you're cutting simple straight grooves or intricate profiled grooves, the CNC Mortising Machine is up to the task. Its versatility makes it suitable for a wide range of applications, from furniture manufacturing to custom woodwork.

Adjustable Processing Dimensions: The CNC Mortising Machine is available in two models, each offering different processing lengths, widths, and heights. This allows users to choose the model that best suits their specific needs, whether they're working on small projects or large-scale production runs.

Robust Construction: Built to withstand the demands of continuous operation, these machines feature a robust construction that ensures long-term reliability. The solid frame and durable components reduce vibration during operation, leading to more accurate cuts and a longer lifespan for the machine.

Investing in a CNC Mortising Machine is a smart choice for any woodworking business looking to improve precision, efficiency, and overall production quality. With their advanced features and versatile capabilities, these machines are set to become an integral part of modern woodworking operations. Whether you're a small shop or a large manufacturing facility, the CNC Mortising Machine can help you stay competitive in an increasingly demanding market.By adopting this technology, woodworking professionals can ensure they are equipped to meet the challenges of today’s industry while maintaining the craftsmanship and attention to detail that their customers expect.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?