Tel:

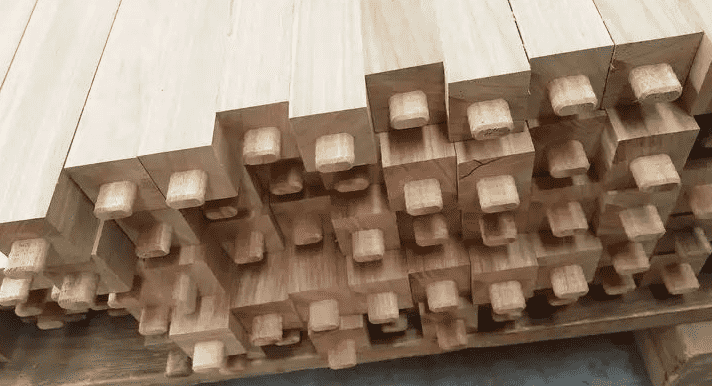

In the rapid development of today's woodworking manufacturing industry, the double-end CNC tenoning machine has become an indispensable and efficient tool for furniture manufacturing and wooden door production industries with its excellent performance and wide application fields. This equipment, which integrates modern CNC technology and precision machining concepts, not only greatly improves production efficiency, but also promotes the intelligent transformation of the entire woodworking industry while ensuring product quality. The core advantage of the double-end CNC tenoning machine lies in its high efficiency. Traditional manual tenoning or single-end mechanical tenoning methods are not only time-consuming and labor-intensive, but also difficult to ensure the accuracy consistency of each product. The double-end CNC tenoning machine can automatically complete the tenon processing at both ends of the wood through a preset program, realizing a one-machine-multi-purpose, one-time molding production mode. This high efficiency not only shortens the production cycle and reduces labor costs, but also wins more market opportunities for enterprises.

1. Guarantee of precision processing

Precision is one of the important evaluation indicators of woodworking machinery, and the double-end CNC tenoning machine performs particularly well in this regard. It uses an advanced CNC system to ensure that the size, angle and shape of each processing can meet the design requirements through precise calculation and control. Whether it is a complex mortise and tenon structure or high-precision dimensional requirements, the double-end CNC tenoning machine can easily cope with it. This precision not only improves the overall quality of the product, but also provides great convenience for subsequent assembly and use.

2. Quickly adapt to market demand

With the increasing diversification of consumer demand for wooden products such as furniture and wooden doors, the market has higher and higher requirements for personalized and customized products. With its flexible programming ability and powerful processing ability, the double-end CNC tenoning machine can quickly adapt to market changes and meet the personalized needs of different customers. Whether it is complex pattern engraving or special shape tenon processing, it can be quickly realized by modifying the program, which greatly improves the market response speed and competitiveness of the enterprise.

3. Leader of intelligent production

Under the background of intelligent manufacturing, the woodworking CNC tenoning machine, as a representative of the intelligent woodworking industry, is leading the transformation and upgrading of the entire industry. Through the integration and application of technologies such as the Internet of Things and big data, the double-end CNC tenoning machine can realize real-time monitoring, data analysis and intelligent optimization of the production process. This not only improves production efficiency and product quality, but also provides valuable data resources for enterprises, helping them to achieve refined management and intelligent decision-making.

4. Wide application, promote industrial upgrading

The application of double-end CNC tenoning machine in furniture manufacturing and wooden door production has become more and more extensive. In the field of furniture manufacturing, it can not only quickly complete the tenon processing of various furniture components, but also seamlessly connect with other automated equipment to form an efficient production line. In the field of wooden door production, the double-end CNC tenoning machine has become the preferred equipment for processing key components such as door leaves and door frames with its high precision and high efficiency. These applications not only enhance the market competitiveness of products, but also promote the industrial upgrading and technological progress of the entire woodworking industry.

Conclusion:

In summary, as a leader in the field of woodworking CNC machinery, the double-end CNC tenoning machine plays an increasingly important role in furniture manufacturing, wooden door production and other fields with its high efficiency, precision and speed. It not only improves production efficiency and product quality, but also promotes the intelligent transformation and industrial upgrading of the entire woodworking industry. With the continuous advancement of technology and the continuous development of the market, the double-end CNC tenoning machine will surely occupy a more important position in the future woodworking manufacturing industry, injecting new vitality and impetus into the development of the industry.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?