Tel:

The woodworking industry has seen significant technological advances over recent years, and CNC dovetail tenoners are at the forefront of this transformation. This powerful tool is reshaping workshops by streamlining the process of cutting dovetail joints, a critical task in cabinet and furniture making. But why exactly are more woodworkers turning to CNC dovetail tenoners? Let’s explore the key reasons behind this trend and why these machines are becoming essential investments.

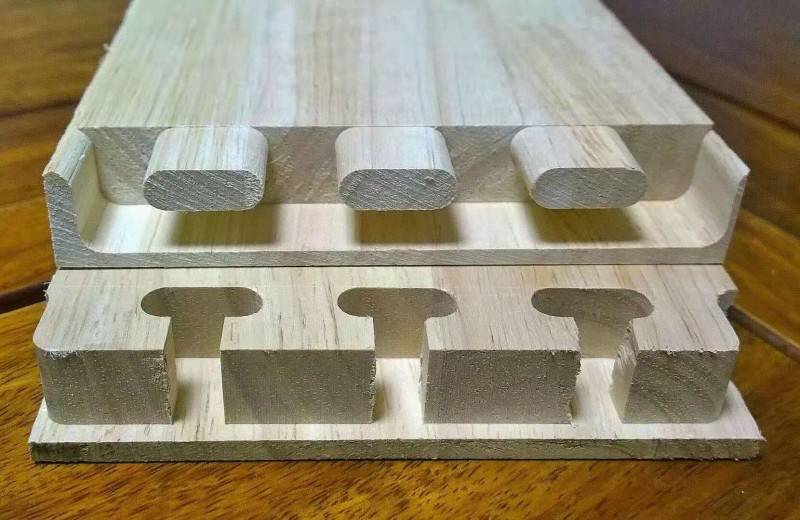

One of the most significant benefits of using a woodworking CNC dovetail tenoner is the precision it offers. Traditional hand-cut dovetail joints, while beautiful, can be inconsistent and time-consuming. A CNC dovetail tenoner eliminates this inconsistency by ensuring that each joint is cut to exact specifications. This not only improves the overall quality of the project but also boosts client satisfaction and repeat business.

Time is money, especially in professional woodworking shops. Cutting dovetail joints by hand or using older manual equipment can take considerable time and effort. However, with a CNC dovetail tenoner, woodworkers can automate the process, drastically reducing the time needed to create complex joints. This increase in productivity allows woodworkers to take on more projects, thereby boosting overall revenue.

Modern CNC dovetail tenoners are designed with user-friendly interfaces, making them accessible to both seasoned professionals and new woodworkers. Many machines come with intuitive software that simplifies programming, ensuring even intricate designs can be executed with minimal learning curves. This ease of use contributes to faster project turnarounds and reduces training time for new operators.

The versatility of CNC dovetail tenoners makes them a preferred choice for woodworkers specializing in various projects, from cabinetry to fine furniture. These machines can handle different wood types and thicknesses, allowing for a broad range of design possibilities. Whether you’re producing custom pieces or fulfilling bulk orders, a woodworking CNC dovetail tenoner can adapt to the task with minimal adjustments.

Although the CNC dovetail tenoner price can vary widely based on brand and features, many woodworkers find that the initial investment pays for itself over time. Machines with advanced capabilities may have higher upfront costs, but their efficiency, precision, and long-term durability often justify the expense. For those who are budget-conscious, searching for a CNC dovetail tenoner for sale from reputable dealers or considering second-hand options can be cost-effective ways to upgrade workshop capabilities without breaking the bank.

Safety is a critical concern in any workshop, and CNC dovetail tenoners contribute to safer working conditions. By automating the cutting process, operators are kept at a safe distance from moving parts, reducing the risk of injury. Additionally, modern machines often come with built-in safety features, such as automatic shut-off and emergency stop buttons, which provide extra layers of protection.

When producing furniture or cabinets, the quality of dovetail joints can make or break a project. A CNC dovetail tenoner ensures that each joint is not only precise but also smooth and professional-looking. This high-quality output not only elevates the craftsmanship of a piece but also increases its value, making it easier to command premium prices for finished products.

In a competitive market, standing out is essential. Investing in a woodworking CNC dovetail tenoner can give workshops a competitive edge by allowing them to take on more complex projects that demand precise joinery. This capability positions businesses as leaders in their field, attracting discerning customers who value craftsmanship and reliability.

By investing in a CNC dovetail tenoner, woodworkers can experience greater precision, efficiency, and versatility. Whether for custom projects or high-volume production, these machines are revolutionizing the woodworking industry.

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

Enhancing Cutting Accuracy and Efficiency with CNC Miter Machines

What Are the Common Mistakes to Avoid in CNC Groove Milling?

What Are the Common Mistakes to Avoid in CNC Groove Milling?

How to Choose the Best CNC Dovetail Machine?

How to Choose the Best CNC Dovetail Machine?

What Should You Look for in a Double End Mortising Machine Manufacturer?

What Should You Look for in a Double End Mortising Machine Manufacturer?